As the global environmental movement sweeps the packaging industry, Europe has long been a key market for recyclable packaging. Italy has mandated certification for the recyclability of food contact packaging, Spain encourages companies to adopt sustainable packaging through policy subsidies, and the EU has set a strict target of achieving a packaging recycling rate of over 70% by 2030. In this market environment, “recyclability” is no longer just a brand advantage, but a standard for entering the international market.

I. Applications of MONO-PE Recyclable Spout pouch

Spout pouch are the mainstream packaging choice for liquid, semi-liquid, and powder products, widely covering the following categories:

• Food Sector: Sauces, condiments, beverages, edible oils, meal replacement powders and other powdered products, liquid complementary foods (infant puree, etc.) – Primarily promoting food-grade materials that have passed EU LFGB certification, with no harmful substances leaching out, meeting European food packaging safety standards;

• Daily Chemical Sector: Laundry detergent, dishwashing liquid, shower gel, shampoo, conditioner – recyclable material aligns with the “green and sustainable” brand promotion of European daily chemical brands;

• Pet Supplies Sector: Pet nutritional solutions, wet pet food, pet shampoo – Appealing to environmentally conscious pet owners;

• Industrial Sector: Automotive antifreeze, car wash liquid, gasoline, lubricants, etc.

II. Material Composition of MONO-PE Recyclable spout pouch

recyclable spout pouch use a combination of all PE materials to ensure “recyclability.” Specific material schemes and technical details are as follows:

1. Adaptable to Different Capacity Needs

1. Adaptable to Different Capacity Needs

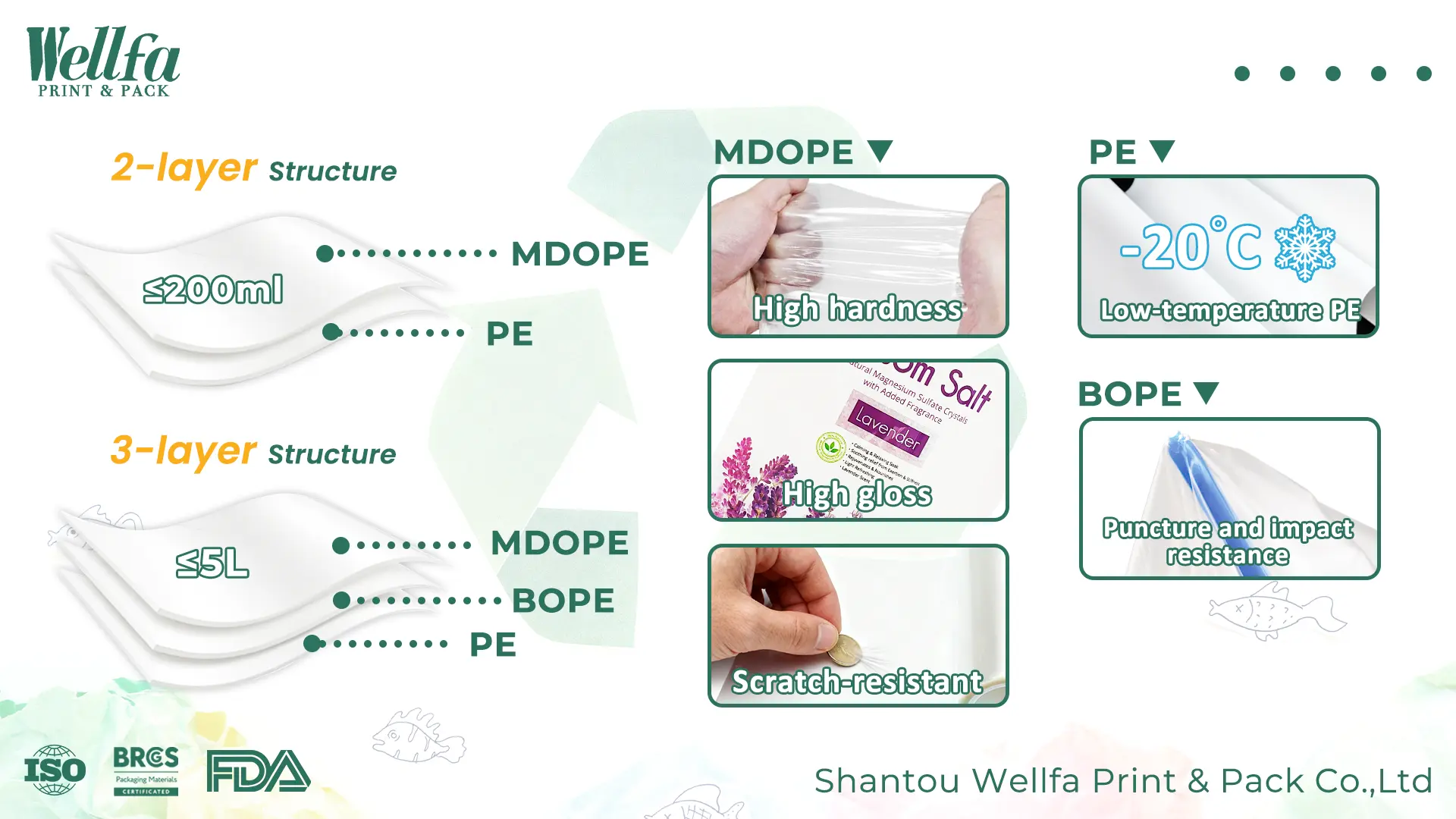

Two targeted material structures are designed based on the capacity of the spout pouch, both meeting recycle standards (all PE system, no composite non-recyclable materials):

• 2-layer structure (suitable for products under 200ml and 1kg): MDOPE (printing layer) + PE / white PE (sealing layer)

MDOPE serves as the printing layer, featuring high hardness and high gloss, clearly displaying brand logos and product information, and is scratch-resistant and fade-resistant; the inner PE / white PE layer is a special low-temperature PE, possessing excellent sealing and low-temperature resistance, maintaining pouch integrity even at -20℃, suitable for refrigerated products.

• 3-Layer Structure (Suitable for products over 200ml, maximum 5L): MDOPE (printed layer) + BOPE (intermediate layer) + PE / white PE (sealing layer)

The intermediate layer BOPE , replaces the traditional NY (nylon), retaining the puncture and impact resistance of NY (suitable for large-volume liquids or sauces containing particles).

2.Key Process: Low-Temperature Processing

2.Key Process: Low-Temperature Processing

Why is the cost of a MONO-PE recyclable spout pouch higher than traditional spout pouches? The core difference lies in the low-temperature processing of the spout and heat-sealing: Traditional spout pouches often use high-temperature rapid heat sealing, but high temperatures can damage the structure of the MONO PE material, making the pouch prone to breakage. Wellfapack’s spout undergoes multiple low-temperature heat sealing + high-pressure shaping processes to ensure a perfect fit between the spout and the pouch body, while preventing material damage. Although this process increases the production steps, it achieves “spout and pouch body made of the same material, recyclable together,” also increasing production costs.

3. Core Features: Recyclable + Practical

3. Core Features: Recyclable + Practical

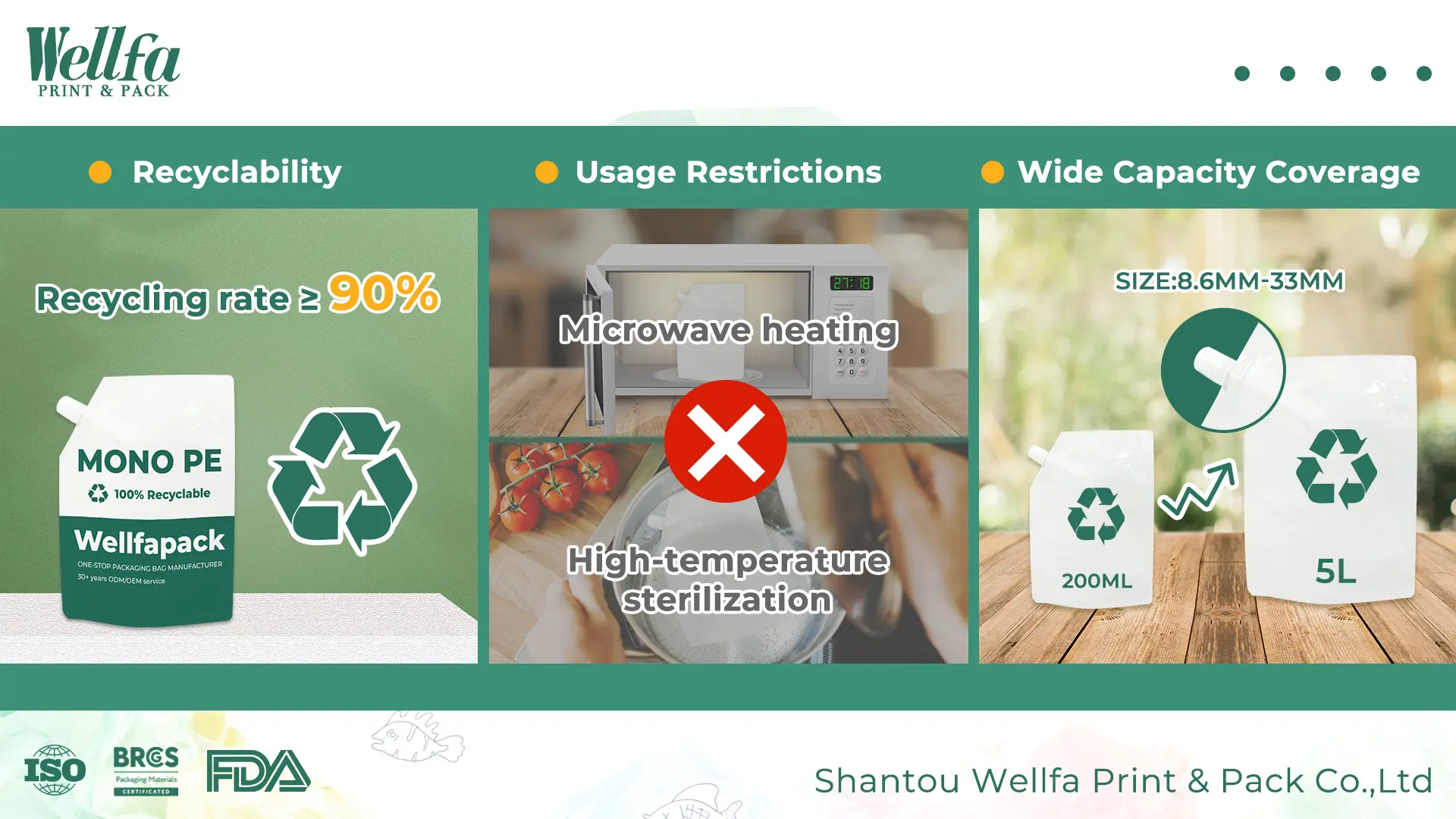

• Recyclability: Made entirely of PE material, it can directly enter the PE packaging recycling process, with a recycling rate of over 90%, fully complying with the EU EN 13432 compostability standard and the Italian UNI 11688 food packaging recyclability certification;

• Usage Restrictions: Not suitable for high-temperature processing (such as microwave heating, high-temperature sterilization), to avoid customer misuse affecting product quality, reflecting our professionalism and rigor;

• Wide Capacity Coverage: From 200ml small capacity (portable juice, sample laundry detergent) to 5L large capacity (family-sized laundry detergent, tub-sized sauce), meeting the capacity needs of different scenarios. The size of the spout is also unrestricted, ranging from 8.6mm to 3.3cm.

III. “Supply Chain Advantages” Make Eco-friendly Packaging More Cost-Effective

For brands in European countries such as Italy and Spain, choosing MONO PE-material recyclable packaging is not only an “environmentally friendly choice,” but also a double benefit of “cost optimization + policy dividends.”

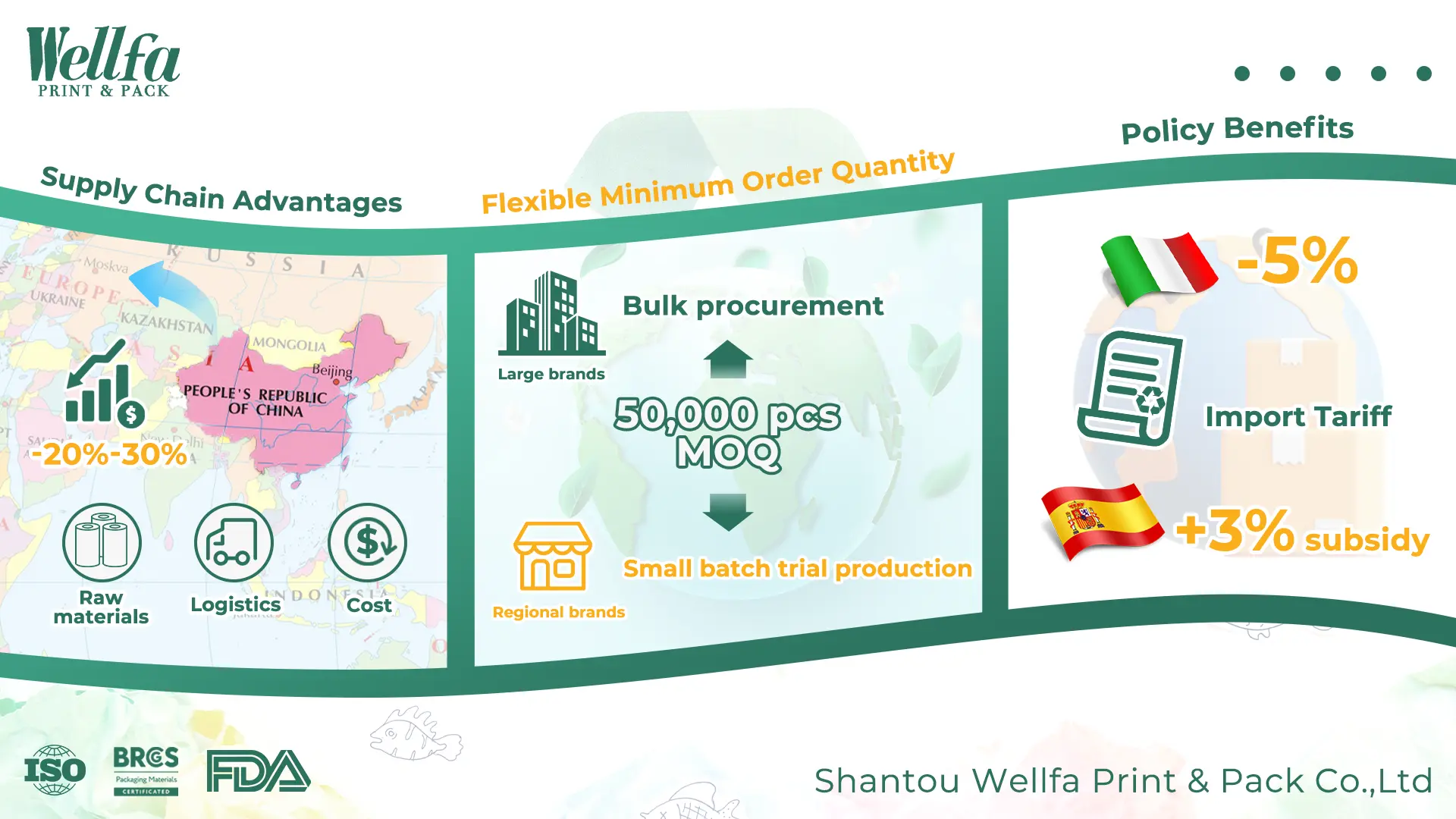

1. Supply Chain Advantages: Made in China, More Competitive Prices

The European market has a strong demand for MONO-PE recyclable spout pouch, but local production faces the problems of “reliance on imported raw materials and high labor costs.” However, relying on China’s complete PE industry chain, 100% of raw materials are sourced domestically (MDOPE, BOPE, and low-temperature PE are all from leading domestic suppliers), eliminating import tariffs and long-distance transportation costs. Production costs are reduced by 20%-30% compared to local European factories, allowing European customers to obtain compliant recyclable packaging at a lower cost.

2. Flexible Minimum Order Quantity: Minimum order of 50,000 pieces, suitable for the needs of small and medium-sized brands

Traditional recyclable packaging often requires a minimum order quantity of 100,000 pieces due to its complex process. By optimizing our production line layout, Wellfa has reduced the minimum order quantity (MOQ) for our MONO PE material recyclable spout pouches to 50,000 units. This satisfies the bulk purchasing needs of large brands while providing startups and regional brands with opportunities for small-batch trial production, helping more brands quickly enter the European environmental market.

3. Policy Benefits: Recyclability Reduces Import Costs

Some European countries offer import tariff reductions for recyclable packaging products (e.g., Italy reduces import tariffs on recyclable food packaging by 5%, and Spain provides a 3% import subsidy for environmentally friendly daily chemical packaging). Wellfapack’s MONOPE-material recyclable spout pouches come with complete recyclable certification documentation (including material testing reports and recycling process instructions), helping customers smoothly enjoy policy benefits during import customs clearance and further reducing overall procurement costs.

IV. Environmental Protection at its Core, Professionalism as its Foundation: Wellfapack, the Sustainable Packaging Partner for Global Brands

• Wellfa firmly believe that “environmental protection is not about sacrificing costs, but about long-term investment”—Wellfapack’s MONO PE-material recyclable spout pouches not only help clients meet policy requirements and enter mainstream global markets, but also enhance their brand image and win consumer favor through their “environmentally friendly attributes” (European research shows that 72% of consumers prefer products with recyclable packaging).

Choosing Wellfapack is not just choosing a spout pouch, but choosing a growth path that aligns with global environmental trends. Let us join hands to protect the Earth’s ecology and create a green future together with recyclable packaging!