如何为您的酱料包装袋选择合适的材料

目录

一、酱料生产商的包装要求

1、Protection for the sauce itself

Barrier property:

酱汁容易氧化, 恶化, mold, and other problems due to the influence of oxygen, 水分, and light.

所以, packaging materials need to have good barrier properties.

例如, Aluminum foil material can effectively block oxygen and light, extending the shelf life of sauces.

Generally, sauce packaging manufacturers will recommend their use to customers.

Sealing property:

Good sealing property is the key to preventing sauce leakage, contamination and bacterial invasion.

Whether it is bottled, bagged or canned, the design and material of the sealing part must be ensured to be in harmony with the machine and remain tightly closed during storage and transportation

2、The convenience of packaging usage

Easy to open and use:

From the perspective of sauce producers, the packaging should be convenient for filling, sealing and other operations to improve production efficiency. From the perspective of consumers, it should be convenient for them to open, store and use.

Convenient to carry: With the increasing demand for takeout, picnics and dining out, the demand for small packages of easy-to-carry sauces has risen. Sauce factories also need their packaging to meet and be convenient for consumers to carry around, be easy to use, and increase sales

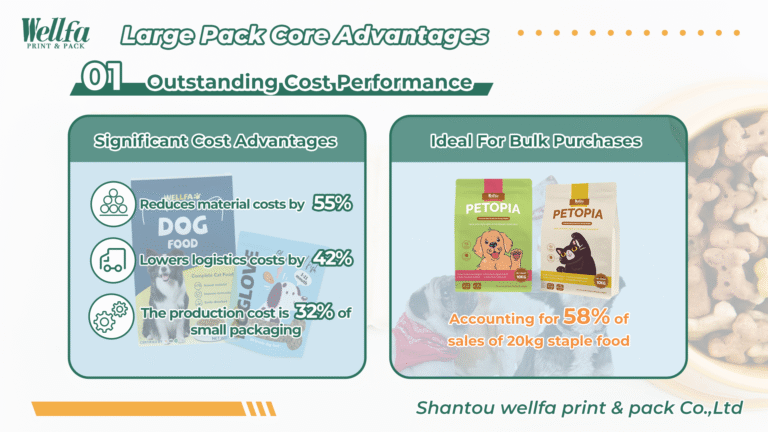

3、Packaging cost

The cost of packaging itself:

The control of the cost of packaging bag materials based on different consumer usage scenarios

Labor costs:

Different machines require different operation processes, which in turn affects whether manufacturers still need to add labor packaging costs

3、Brand display

Unique packaging shapes, 颜色, patterns and printing can highlight brand characteristics and stand out in the highly competitive market

二、suitable packaging materials for sauces

When choosing the packaging material for your sauce that suits you, apart from whether you prefer a glossy surface, matte finish, or UV printing, the most important thing is to select the material composition structure based on the characteristics of the sauce itself

The following are some frequently used materials

1: 铝箔

Aluminum foil is the most suitable barrier material for sauces and is also the most chosen by customers. The permeability of both moisture and oxygen can be minimized. Generally, the packaging of aluminum foil is a bit thicker, with a more solid surface that is less prone to leakage. It also protects the sauce and extends its shelf life.

而且, this material is easy to tear and is often used in sachet. It has a small capacity, making it convenient for customers to tear open the package for use.

2: Vmpet foil

This material also has certain barrier properties against moisture and oxygen, but its grade is slightly lower than that of aluminum foil. Of course, the cost will also be a little lower. It is suitable for selling sauce brands with relatively low unit prices but requirements for barrier properties.

3: White Pe

The material White pe is an alternative to aluminum foil and vmpet foil

It has a certain function of blocking acidity and alkalinity. It is mostly used when customers do not like foil in the bag material and hope to reduce the recycling cost of the bags. And considering that most sauces are dark in color, if the design of the light-colored surface needs to block the color of the contents to avoid affecting the appearance through the packaging. This is the best choice and the cost is relatively low

4: evoh

EVOH is a high-barrier material.

It is mostly used for packaging made of recyclable materials. If the customer’s sales market is Europe or a country with requirements for recyclable packaging. Many customers will choose EVOH to replace Aluminum foil or Vmpet foil or WHITE PE

The disadvantages that need to be taken into account are that the minimum order quantity of this material is high, and the capacity of recyclable packaging is generally limited, as well as the thickness limit of the packaging is relatively high. This reduces the limitations of bag customization

5: RCPP

RCPP is generally an essential material in high-temperature steamed and retort materials

If the sauce requires a production process of high-temperature sterilization, this material is indispensable.

There are generally 121° and 135° grades. The composition of the material should be determined based on the machine’s temperature and heating time. This is also the current tendency of large sauce factories or brands. As more and more people pay attention to food safety, high-temperature sterilization is an indispensable production process for sauces to be used for a long shelf life

6: 这

Most sauces are products containing liquid and paste. NY is a material with high ductility.

It maximally protects the bags from impact and compression during filling and transportation. It is also a basic and essential ingredient for sauces larger than 500ml

If you are also looking for custom packaging for sauces, 请随时 联系我们. We are a factory with 33 years of experience in custom packaging.

Not only can we recommend suitable packaging materials for your products, but we can also help you recommend packaging machines that suit you.

We offer you a complete customized solution to make your brand and products stand out