Выберите правильные материалы для вашего мешочка

Оглавление

Носик является инновационным и практическим упаковочным решением, которое широко используется в еде, напиток, ежедневное химическое вещество, фармацевтический, и другие отрасли.

Это не только удобно носить и хранить, Но это также может эффективно уменьшить упаковочные отходы, который соответствует текущей тенденции защиты окружающей среды.

Выбор соответствующих материалов для мешочков играет решающую роль в производительности, функция, расходы, и защита окружающей. Неправильный выбор материала может вызвать утечку продукта и ухудшение, повлиять на имидж бренда, и увеличить затраты; Напротив, Правильный выбор материала может улучшить качество продукции и конкурентоспособность рынка, и принесите более коммерческую ценность на предприятие.

1 、Характеристики продукта и требования к материалам для извержения мешочка

Емкость

В настоящее время, мешочек может принять индивидуальный спрос от 30 мл до 10 литры

При поддержке продуктов большого объема, требуется ключевой материал - Нью -Йорк (Нейлон) – характеризуется его эластичностью и способностью эффективно предотвратить проколоту упаковки, обеспечение целостности продукта и герметизации пакета.

Специальные требования к температуре и использованию

Много жидких продуктов, такие как молоко или соус, иметь требования к температуре заполнения,Долгосрочное хранение и необходимо пастеризовать 100 градусов или стерилизован при высокой температуре 121Degree-135Degree . Они обычно требуют материалов, которые могут противостоять высокотемпературному заполнению, Высокие свойства барьеры и приготовление пищи.

Алюминиевая фольга и фольга Vmpet - это барьерные материалы, которые соответствуют вышеуказанным требованиям.

Метод хранения и стоимость

Метод хранения также имеет высокие требования для материала из лобкового мешочка, например, если продукт необходимо заморозить до -18 ° C или хранить при комнатной температуре для более чем, чем 1 год, Материал должен быть в состоянии хорошо защищать содержимое и предотвратить ухудшение и утечку.

Кроме того, по сравнению с традиционными бутылками и стеклянными банками, Спустя, иметь низкие транспортные расходы, и очень безопасны.

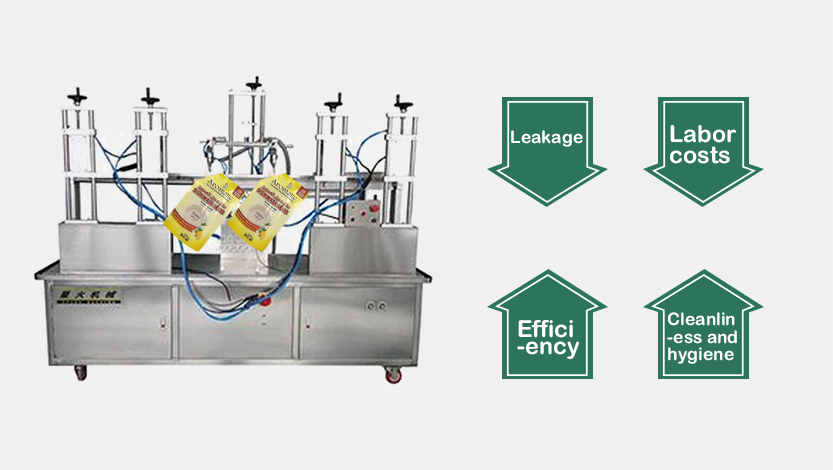

Метод заполнения

Высокое использование ежедневных потребностей также требует большого ежедневного объема производства. Это также требует высокой скорости производства, и машинное наполнение является незаменимым методом производства для извержения мешочков.

Точный размер сопла идеально доки с машиной, что уменьшает утечку во время наполнения, повышает эффективность, снижает затраты на рабочую силу, и защищает чистоту и гигиену упаковки продукта.

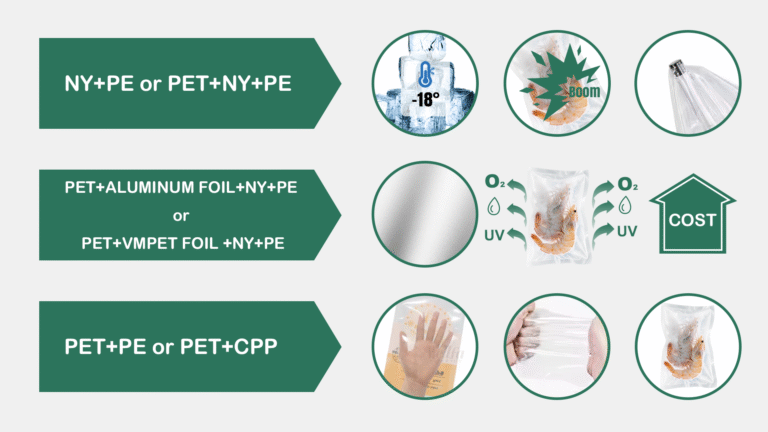

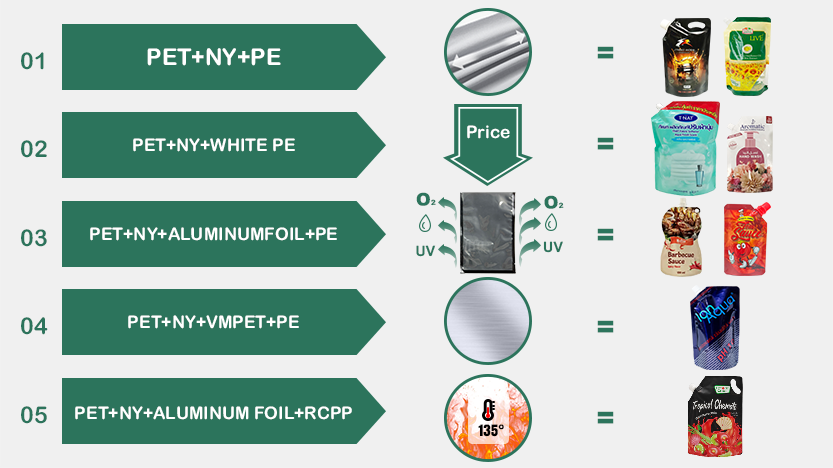

2、Обычно используемые комбинации материалов из носика и их функции

PET+NY+PE

PET может соответствовать требованиям проектирования из лобковых мешочков, они глянцевые, матовый, или UV-эффект. По сути, Это первый слой из лобкового мешочка.

Нейлон имеет сильную прочность, будь то жидкость или продукт с частицами. Он может защитить безопасность самого сумки во время транспортировки и хранения.

Эта комбинация является наиболее распространенной и наиболее часто используемой структурой

PET+NY+Y+NYTHITH

Разница в структуре материала PET+NY+PE заключается в том, что последний слой этой структуры, то есть, Белая фи. .

Эта структура чаще всего используется в химических продуктах, такие как стиральное порождение, чистящие средства и другие продукты с кислотностью и щелочной, но не требуют сильных барьеров. Поэтому, Белая PE является относительно недорогим вариантом по сравнению с чистым алюминиевым и алюминиевым покрытием.

ПЭТ + Алюминиевая фольга + PE

Алюминиевая фольга является относительно дорогой структурой промежуточного слоя, широко используется в продуктах с длительным сроком годности, которые должны блокировать кислород, влага, и ультрафиолетовые лучи.

Эта структура материала широко используется в высококачественных чистящих средствах, соусы, и ежедневные приправ

PET+NY+VMPETS+PE

Vmpet (металлик) имеет более низкую стоимость, чем алюминиевая фольга, Но это также имеет тот же барьерный эффект. Это также подходит для продуктов, которые требуют барьеров, но имеют более низкую стоимость и продажи.

Кроме того, Металлический блеск фольги Vmpet может усилить внешний вид упаковки, Делать продукт более привлекательным на полке и привлечение потребителей’ внимание.

PET+NY+Алюминиевая фольга+RCPP

Эта структура материала в настоящее время наиболее широко используется для продуктов, которые требуют высокотемпературной стерилизации и реторта продукта.

Замените последнюю структуру слоя на RCPP. Он может противостоять высокой температуре до 135 градусы и имеют сильный барьерный эффект.

В настоящее время, молочные продукты, Детские дополнительные продукты питания, и т. д., иметь высокие требования к безопасности пищевых продуктов и необходимо легко допускать порчу пищи, и эта материальная структура будет выбрана

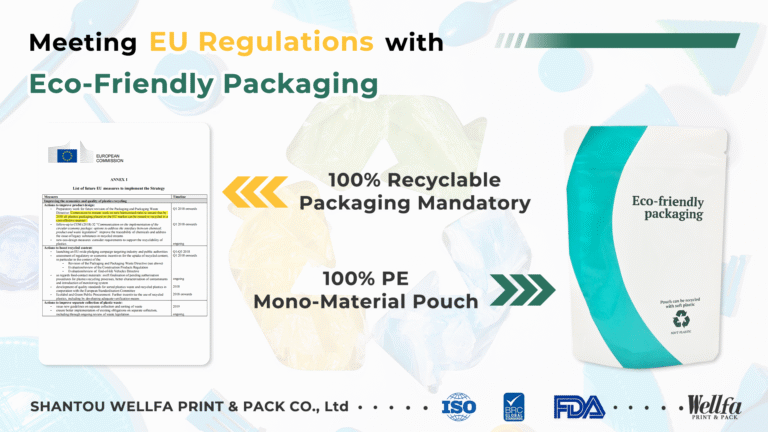

Выбор материала из лобкового мешочка является сложным и критическим процессом, который требует всестороннего рассмотрения характеристик продукта, Функциональные требования упаковки, Бюджет затрат, и устойчивое развитие. Разные материалы обладают своими уникальными свойствами и характеристиками. Никакой материал не подходит для всех ситуаций. Операции должны сделать лучший выбор, основываясь на конкретных потребностях их продуктов.

В этом процессе, Это мудрый выбор, чтобы сотрудничать с профессиональной упаковочной компанией. Профессиональные упаковочные компании имеют богатый опыт и профессиональные знания. Они могут предоставить персонализированные упаковочные решения в соответствии с потребностями предприятий, Помогите предприятиям выбрать наиболее подходящие материалы, Оптимизировать дизайн упаковки, улучшить качество упаковки, и сократить расходы.

В то же время, Профессиональные упаковочные компании также могут идти в ногу с тенденциями развития отрасли, предоставить предприятиям новейшие материалы и техническую информацию, и помочь предприятиям сохранить лидирующую позицию в конкуренции рынка.

Надеюсь, что эта статья поможет компаниям лучше понять выбор материалов из носика и создать высококачественную упаковку, которая отвечает как потребностям в продукте, так и на рыночных тенденциях. Если у вас есть какие -либо потребности, ты можешь Свяжитесь с Wellfa Упаковка в любое время, чтобы получить наиболее удовлетворительное решение упаковки для вас.