Een uitgebreide gids voor het aanpassen van plastic verpakkingszakjes

Een uitgebreide gids voor het aanpassen van plastic verpakkingszakjes

I. Invoering

In today’s competitive market, the importance of custom packaging cannot be overstated. From establishing brand identity to ensuring product protection, the right packaging can make all the difference. Plastic packaging pouches, in particular, have become a popular choice due to their versatility, cost-effectiveness, and adaptability. For those seeking quality materials, consider exploring the offerings of an Aluminium Foil Roll Manufacturer. This article aims to provide a comprehensive guide on how to customize the right plastic packaging pouches for your products. We will delve into the various aspects to consider, from understanding your product to choosing the right materials and design, ensuring a seamless experience for both your brand and your customers.

II. Understanding Your Product

A. Type of Product

The first step in customizing your plastic packaging pouches is to understand the type of product you intend to package. Different products have varying requirements, and the packaging must cater to these needs. For instance, food products often require packaging that provides barrier protection against moisture, zuurstof, and light to preserve freshness and extend shelf life. Liquids and beverages need leak-proof and spill-resistant options, while pharmaceuticals and cosmetics may require tamper-evident features to ensure safety and integrity.

B. Product Specifications

Consider the specific characteristics of your product, such as its weight, volume, fragility, and shelf-life. A lightweight snack product, for example, will have different packaging needs compared to a bulky and heavy liquid detergent. Fragile items might require additional cushioning or protective layers within the pouch, while products with a shorter shelf life may benefit from high-barrier materials to maintain quality over time.

C. Packaging Requirements

Identify the essential packaging requirements based on your product’s needs. These might include barrier properties for moisture, zuurstof, and light protection, resealability for convenience, or particular formats that enhance usability. Addressing these requirements early in the process will guide your material and design choices, ensuring that the final product aligns with your goals.

III. Materiaalkeuze

A. Types of Plastic Materials

Selecting the right plastic material is crucial for the effectiveness of your packaging. Common materials include:

- Polyethylene (PE): Known for its flexibility and durability, PE is often used for dry foods, frozen products, and liquids.

- Polypropylene (PP): Offers excellent clarity and resistance to high temperatures, making it ideal for packaging that requires sterilization.

- Polyethylene Terephthalate (PET): Provides strong barrier properties against moisture and oxygen, suitable for products that require longer shelf life.

Each material has its unique properties, and understanding these can help you choose the most suitable one for your specific needs.

B. Environmental Considerations

With the growing emphasis on sustainability, considering environmentally friendly materials is vital. Options include:

- Recyclable Plastic: These materials can be recycled into new products, reducing waste.

- Biodegradable Plastic: Capable of breaking down naturally over time, minimizing environmental impact.

- Compostable Plastic: Designed to decompose in composting conditions, contributing to soil health.

Choosing sustainable materials not only reflects a commitment to corporate social responsibility but also resonates with eco-conscious consumers.

C. Durability and Flexibility

Your packaging material must strike a balance between durability and flexibility. The pouch should be robust enough to protect the product during handling and transportation while remaining flexible for easy usage. Bijvoorbeeld, stand-up pouches require a certain rigidity to maintain their structure, while gusseted pouches need flexibility for expanding when filled.

IV. Design and Functionality

A. Pouch Formats

Selecting the right pouch format is essential for functionality and customer convenience. Common formats include:

- Stand-Up Pouches: Popular for their ability to stand upright on shelves, enhancing visibility and accessibility.

- Flat Pouches: Suitable for single-serving products or items that do not require self-standing capabilities.

- Gusseted Pouches: Offer additional volume and stability, ideal for bulkier or heavier products.

Each format has its advantages, and the choice depends on the product’s nature and how it will be displayed and used.

B. Closure Mechanisms

The closure mechanism is a critical component of pouch design, impacting usability and product preservation. Options include:

- Zippers: Provide resealability for multi-use products, enhancing freshness and convenience.

- Spouts: Ideal for liquid products, ensuring controlled dispensing and spill prevention.

- Tear Notches: Facilitate easy opening, especially for single-use packages.

Selecting the appropriate closure mechanism can greatly enhance the user experience and product satisfaction.

C. Aesthetic Elements

Aesthetics play a significant role in attracting customers and reinforcing brand identity. Consider how colors, print designs, and transparency options can impact the overall look of your packaging. Bijvoorbeeld, vibrant colors and bold graphics can make your product stand out on the shelf, while a window in the pouch can allow consumers to see the product inside, building trust and appeal.

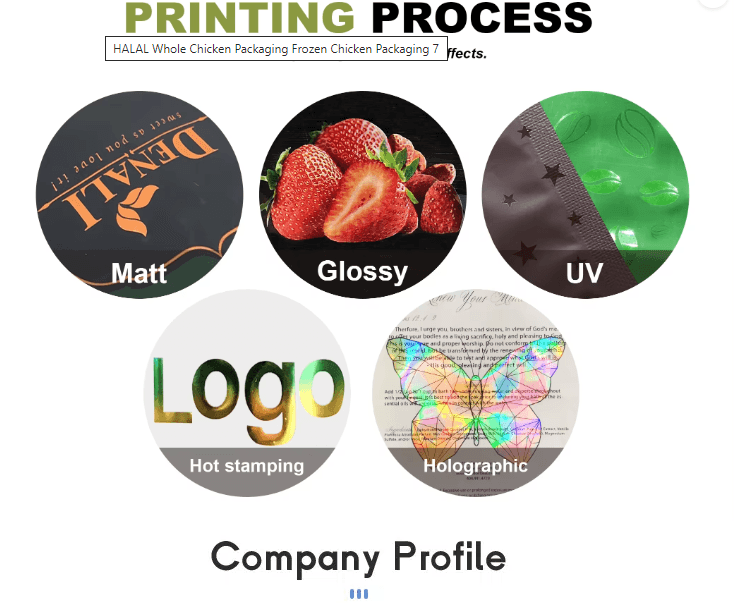

V. Printing and Branding

A. Custom Print Options

Printing is an integral part of custom packaging, allowing you to showcase your brand and product information. Two common printing methods are:

- Flexographic Printing: Suitable for high-volume orders, offering cost-efficiency and quality.

- Digital Printing: Ideal for smaller runs and designs that require frequent updates, providing flexibility and vibrant colors.

Understanding the strengths of each printing method will help you choose the best option for your packaging needs.

B. Branding Elements

Your packaging is a powerful branding tool. Ensure that your logo, brand colors, and typography are prominently displayed and aligned with your brand identity. Consistency in branding across different products strengthens brand recognition and loyalty.

C. Legal and Regulatory Information

Including necessary product information and compliance labels is essential. This might cover ingredients, nutritional facts, usage instructions, expiry dates, and regulatory symbols, depending on the product and market requirements. Ensuring this information is clear and accurate helps build consumer trust and meets legal obligations.

VI. Supplier Considerations

A. Researching Suppliers

Finding a reliable supplier is crucial for the success of your custom packaging project. Look for suppliers with a good reputation, positive reviews, and a proven track record in producing high-quality packaging.

B. Sample Testing

Before committing to a large order, request samples from potential suppliers. This allows you to assess the material quality, print accuracy, and overall feel of the packaging. Use these samples to test how the packaging performs under real-world conditions.

C. Minimum Order Quantities and Lead Times

Understanding the supplier’s policies on minimum order quantities (MOQs) and lead times is important. Ensure that their production timeline aligns with your product launch schedule and demand. This helps prevent any delays or issues in your supply chain.

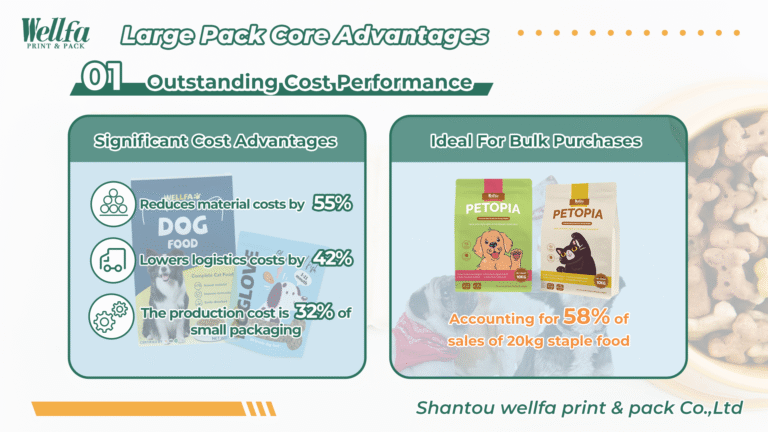

VII. Cost Analysis

A. Budget Considerations

Balancing cost with quality is key in packaging decisions. Identify your budget constraints and prioritize features that are most important for your product. Sometimes, investing slightly more in high-quality packaging can pay off through increased consumer satisfaction and brand perception.

B. Bulk Order Discounts

Many suppliers offer discounts for bulk orders. Consider the potential savings when ordering larger quantities and evaluate if it aligns with your product’s sales volume and storage capabilities.

C. Hidden Costs

Be aware of hidden costs, such as shipping, customs duties, and potential waste. Ensure that these costs are factored into your budget to avoid surprises and maintain profitability.

(下一段)