구운 닭고기 가방의 장인 정신: 전자레인지 패키지의 혁신

목차

With the characteristics of being lightweight and high-temperature resistant, roasted chicken bags have become an important choice for packaging in roasted chicken chain stores and supermarket brand foods. High-quality products need to balance practicality and convenience in detailed design. This article focuses on their customizable materials and printing, heat anti-fog properties, microwave usability, as well as customizable handle, bottom, zipper, and vent designs, and analyzes their functional values.

Window Kraft Paper roasted chicken bags

- Made of natural kraft paper as the base material, with a transparent window design.

- Eco-friendly, conforming to the concept of green consumption.

- Has good stiffness and load-bearing capacity, not easy to break.

- Supports various process printing, such as gold stamping and embossing, to enhance texture.

- Suitable for scenarios that value environmental protection and product display effects.

Plastic Window Design roasted chicken bags

- Mainly using a combination of PET and CPP paired with a window structure.

- Low cost and high cost performance, saving packaging expenses.

- Good flexibility and sealing performance, locking in the aroma and moisture of the roasted chicken.

- Strong printing adaptability, meeting basic brand promotion needs.

- Suitable for cost-sensitive scenarios with large demand such as fast food chains and takeaway delivery.

PET Oven-Use Material roasted chicken bags

- Made of food-grade PET material with excellent high-temperature resistance.

- Can be directly used in oven heating scenarios without releasing harmful substances.

- High transparency, facilitating observation of the heating status of the roasted chicken.

- Good mechanical strength, impact and wear resistance, suitable for home baking and restaurant kitchens.

핸들 디자인: Humanized Single-Hole vs. Multi-hole handles Options

Single-Hole Handle:

- Monolithic molding process

- 3-4 cm diameter opening (finger or hanging cord compatible

- Streamlined and space-efficient design, ideal for small bags or individual use

• Dual-hole or triple-hole handles:

- Adopt a symmetrical layout with a hole spacing of 8-10 centimeters.

- Enable two-handed carrying to disperse pressure, avoiding indentations on the hands.

- Suitable for multi-person scenarios such as family dinners and outdoor picnics.

Zipper Design: The Perfect Balance of Sealing and Ease of Use

- Material & Structure: Food-grade PE material with interlocking ridges, featuring a 1.5 cm-wide zipper tailored to bag opening length.

- Multiple zipper possibilities, driven by R&D strength to promote product upgrading:

Finished bags can be pre-opened with zippers for user convenience.

With R&D and mold-making capabilities, it can provide customized needs such as single-layer zippers, double-layer zippers, and triple-layer zippers.

Advantages of Microwave Roasted Chicken Bags

Adopt tear-resistant food-grade materials to ensure safe use and packaging stability

Can withstand high temperatures of 100°C without deformation, meeting the needs of microwave heating scenarios

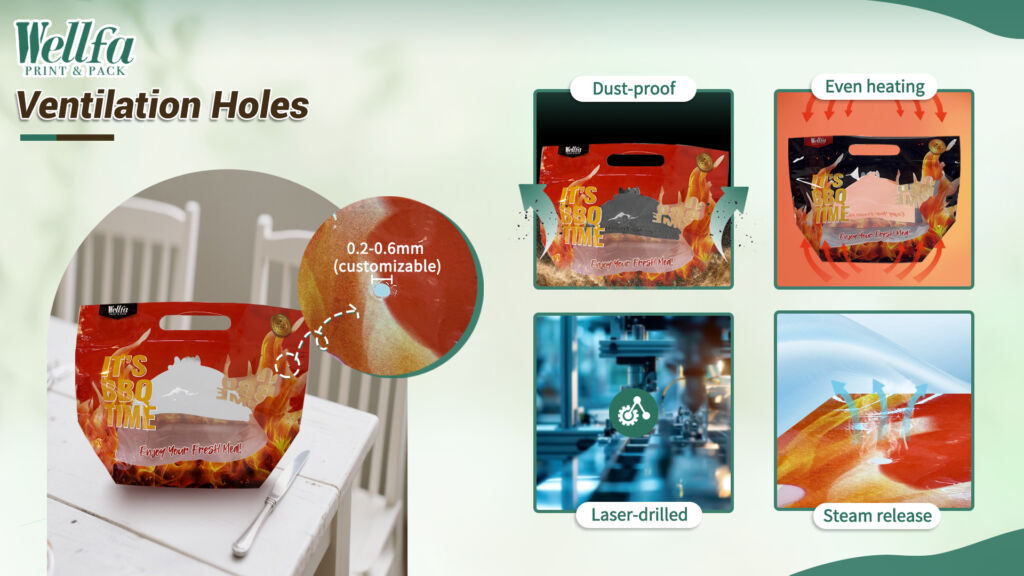

Key Parameters: Located below the zipper, with a diameter of 0.2-0.6 mm (customizable), evenly distributed 2-4 holes per bag.

- The packaging process effectively expels the air inside the zippers,increases the number of individual cartons in a single box,and enhances the efficiency of container loading,

Core functions:

- Blocks dust at room temperature.

- Releases steam slowly during microwave use to prevent the bag from expanding and bursting.

- The flow-limiting design maintains stable temperature, ensuring the chicken is heated evenly and avoiding burnt skin.

Craftsmanship Details:

- Rounded edges, laser-drilled for a smooth burr-free finish that prevents hand injuries or food snagging, reducing the need to frequently open the oven lid for checking.

결론

he design of handles, bottoms, zippers and ventilation holes of roasted chicken bags revolves around the core needs of “practicality” and “safety”. It solves the pain points of traditional products such as handling, sealing and leakage prevention. Through optional solutions, it adapts to different scenarios, making baking more worry – free and retail more secure. 동시에, the size of the roasted chicken bag can be customized according to the specific needs of customers to meet the packaging requirements of roasted chickens of different specifications; The printed logo graphics can also be made according to the customer’s design requirements to help brand publicity and promotion.

If you’re looking for reliable roasted chicken bag solutions, 문의하기 오늘! We are happy to provide product catalogs and free samples so you can experience the quality of our bags firsthand. 귀하의 요구에 가장 적합한 포장 솔루션을 찾도록 도와 드리겠습니다.!