How to choose your sauce packaging based on your machine

Inhaltsverzeichnis

As global culinary cultures converge, the sauce market is booming. With their diverse flavors and versatile uses, sauces have become an indispensable element on the dining table.

Sauce packaging plays a crucial role. It not only protects the sauce’s quality and extends its shelf life, but also significantly impacts brand image, product marketing, and user experience.

Here are several Tips we recommend to find the best packaging for sauce product.

TIPS NO. 1 Different Sauce Packaging Types

1. Disposable Types

1)Roll Film –Sachet

Features: Convenient and compact, suitable for single use and easy portability, often found in fast food restaurants and for takeout delivery.

2) Stand-Up Pouch

Features: Suitable for cooking sauce packaging, with a large capacity and long shelf life, requiring high-temperature retort materials. Suitable for sauces that can be opened and used immediately after heating, as well as ready-to-eat sauces containing meat or mixed vegetables.

- Roll film-sachet

- stand-up pouch

2. Reusable Types

1)Stand-up pouch with spout: This type of packaging is often used in ketchup, salad dressing, and other household sauces that need to be reused multiple times.

This type of pouch is also the most machine-friendly, requiring different opening and filling methods. Different spout pouches are required for different opening and filling methods.

- (1) Spout on top: Fill directly from the top.

- (2)Spout on the side: Fill directly from the spout.

- (3)Spout on the side with open top: Open the top of the bag, fill, and then heat-seal.

2 ) Plastic Bottle

Features: Sauce packaging that does not require barrier materials, requiring only the exterior design of the bottle

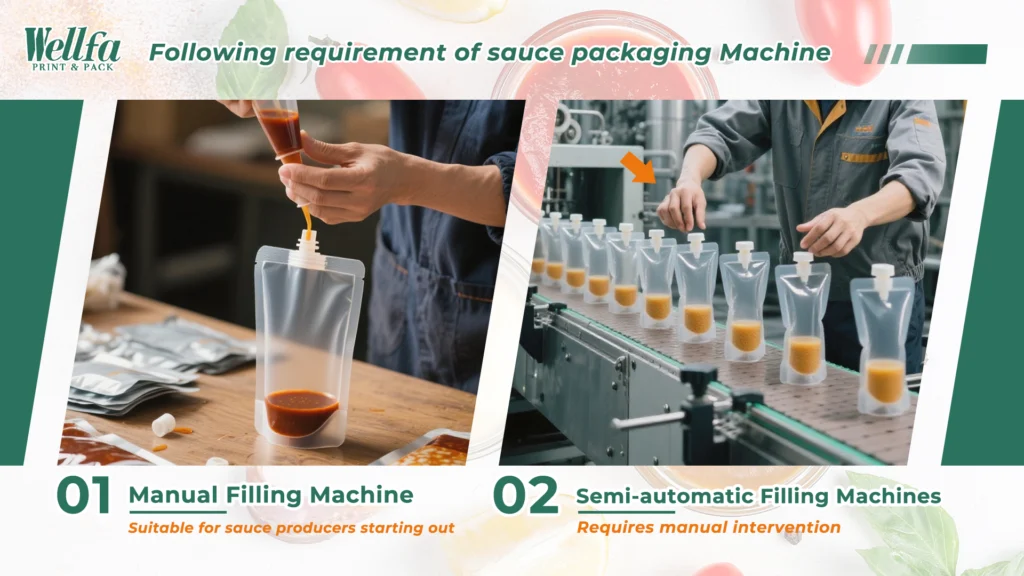

TIPS NO.2 Following requirement of sauce packaging Machine

1. Manual Filling Machine:

Suitable for stand-up pouch with spout and stand-up pouch packaging types, this method requires only filling from the top and sealing the top with a cap oder heat-sealing machine. The advantage is that it doesn’t require a machine, saving costs. However, it’s only suitable for sauce producers starting out, as it’s slow and inefficient. Außerdem, if the cap isn’t tightened tightly enough or the sealing machine’s temperature isn’t properly controlled, leakage can occur during transportation.

2. Semi-automatic filling machines

This type of machine is suitable for stand-up pouches with spouts located on the side or top. It eliminates manual filling and improves efficiency. It can can 6-10 bags simultaneously, but the cap still needs to be manually placed on the bag and then tightened by the machine.

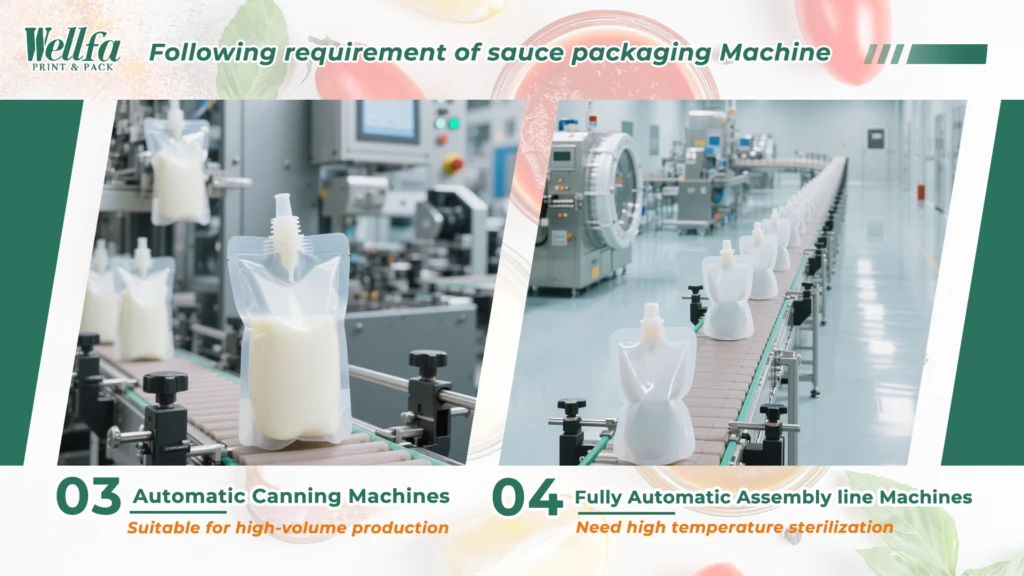

3. Automatic canning machines

This type of machine is suitable for high-volume production. From filling the sauce into the bag to sealing or tightening the cap the machine automatically performs all the steps, eliminating labor costs and improving efficiency. However, the machine cost is higher, making it suitable for factories with high production volumes.

4. Fully automatic assembly line machines

Sauces are products that require a high shelf life and food safety. daher, some high-end sauce factories use high-temperature steaming for sterilization to ensure a long shelf life and maintain the food safety level of the packaging.

From sauce production to filling into the bag and then high-temperature sterilization, all processes are performed on a single aseptic assembly line. This machine requires a packaging bag material that is compatible with the machine’s temperature and a filling method that is suitable for the machine.

5. Automatic Roll Film Packaging Machine

Sachet-type sauce packaging is suitable for small, single-use packages, typically under 10-50g. This machine integrates filling, packaging, and sealing, making it convenient, efficient, and relatively cost-effective, making it suitable for factories producing small-volume sauces.

6. Heat Shrink Machine

Heat shrink film is the most commonly used packaging for bottled sauces to enhance the appearance of the bottle. There are semi-automatic machines that require manual application of the shrink film, as well as roll-type machines that directly cut the film, apply it to the bottle, and then automatically shrink it.

TIPS NO. 3

Choosing a sauce packaging machine and sauce packaging are inextricably linked. Choosing the right packaging bag that best suits your budget, product, production efficiency, and machine operation requires considerable time and experimentation.

If you are looking for sauce packaging suitable for your machine, or are struggling to choose the right machine for your needs, please contact wellfa. We have 33 years of experience in packaging solutions. Please feel free to contact us if you need any assistance.